just thought i may go ahead and add this in here so that i would have my FULL build diary in one place.... (copied from another thread i started)

this install took me just over an hour (timed) from fairings off to back on again. i have never done this mod before, but had taken apart the clutch before (

http://www.suzukihayabusa.org/forum/index.php?topic=70006.0)....

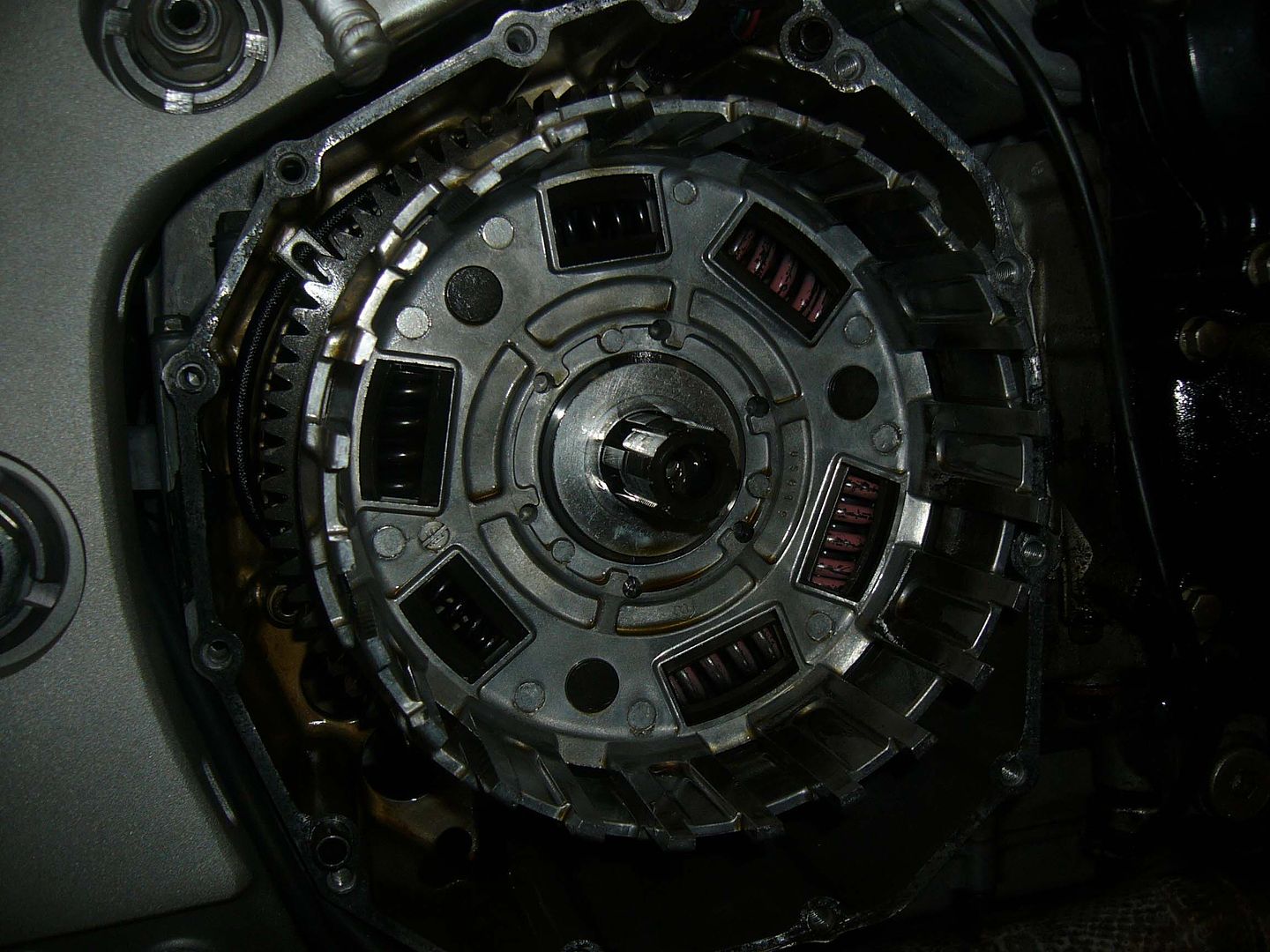

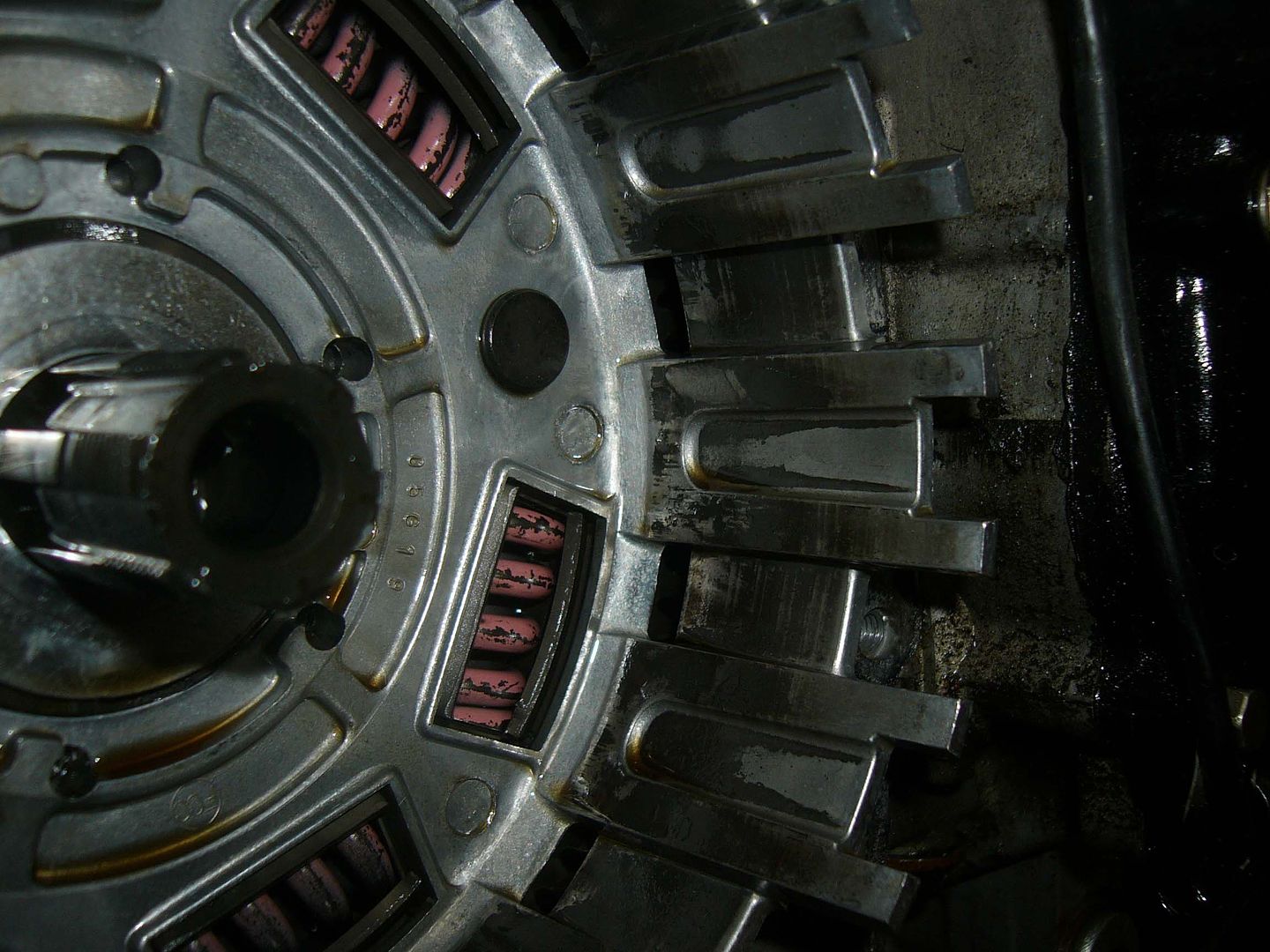

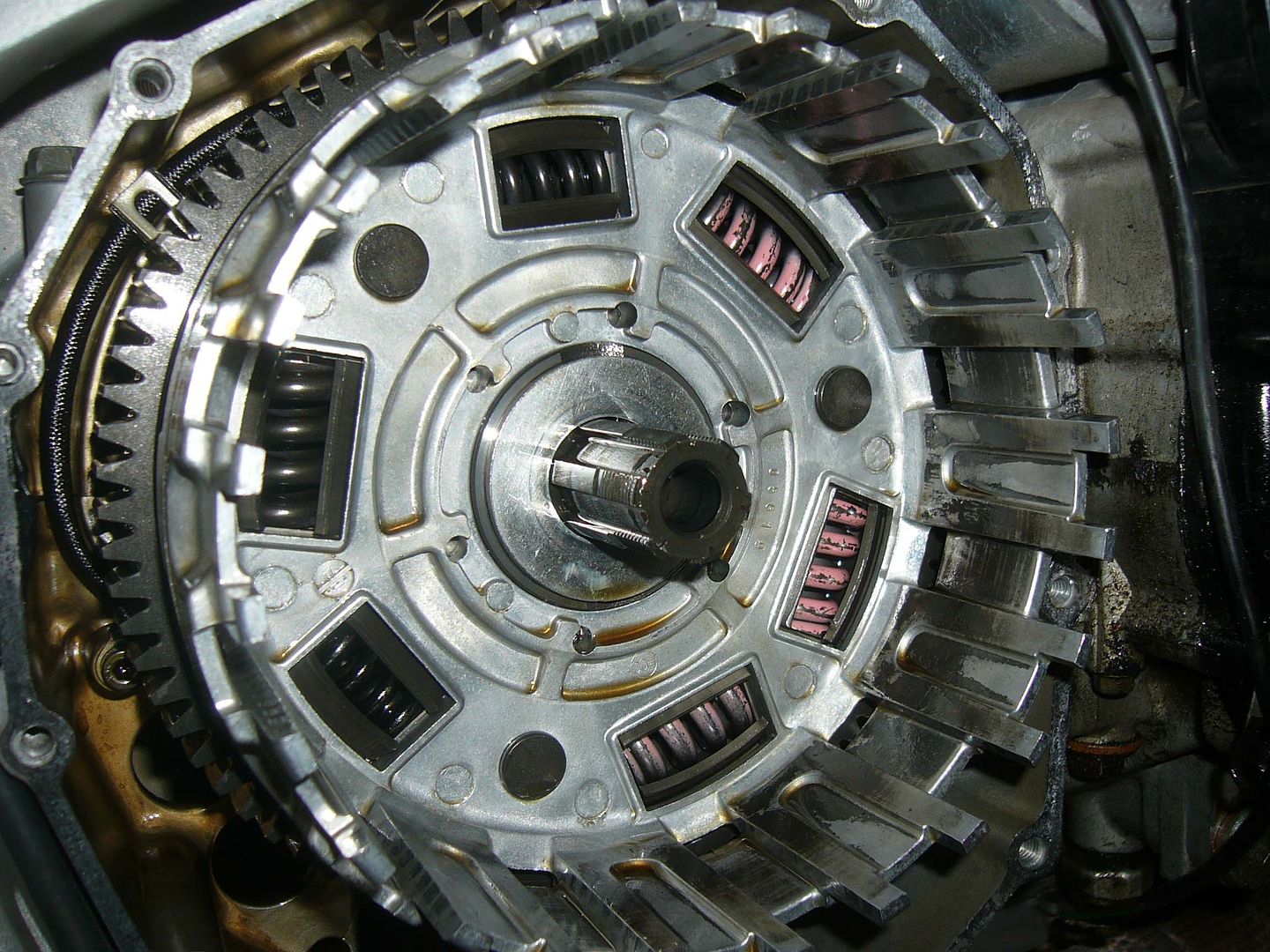

i took off the fairings, and removed the clutch cover. i left it on the kickstand, and this was enough tilt that there was no oil in the clutch basket area. i have also done the kickstand ground out mod...anyways, took off the out pressure plate and removed the clutch plates, leaving them in order and same direction, so as to not mix them up, not sure if important, but no use in in, right? took of center bolt that holds the inner hub. talk about a pain in the neck! when removing the bearings, they all really stayed together pretty well, so i just made sure to be gentle with them so that i wouldn't have to mess with them and add more work

. so then i took off bolts from stock clutch cam thingy, then retorqued them with locktite onto the one piece replacement. it said use red, but all i had was blue, so i just put on a little extra

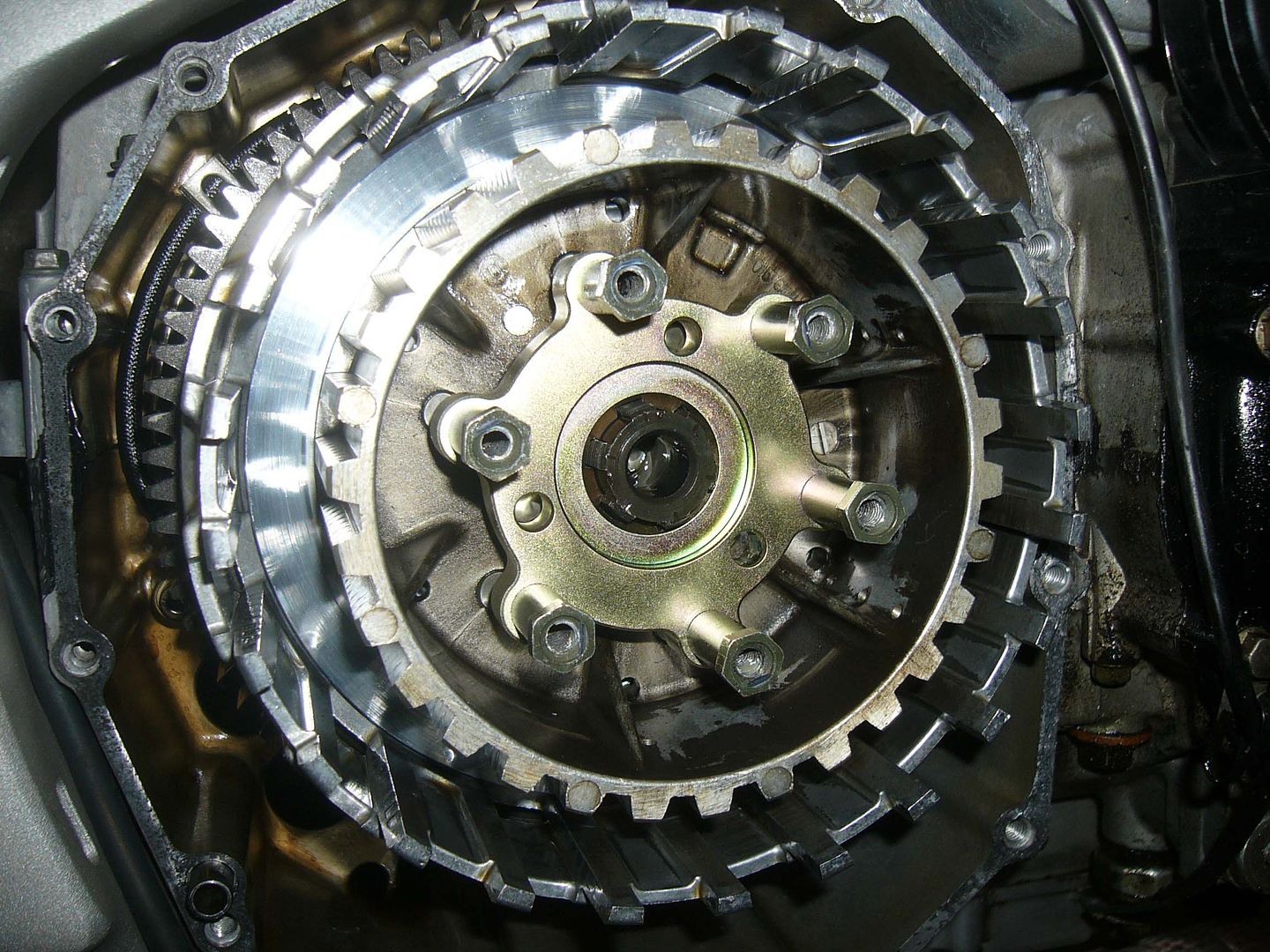

. then i began to reassemble. everthing was going good, until i had to torque down the inner hub retaining bolt. it is at like 68.5 ft/lbs or something rediculous, at least when the bolt threads you are tightening to are not fixed... SO, what to do??? well, i got a large plybar that i got and put it in between two or the clutch spring bolts that i had put on earlier and then tried to torque down. this worked!!!! but i am not sure that i would like to do this one again...the manual shows a special tool that grips the 'teeth' of the inner hub, and naturally, who has one of those just laying around at home? so the plybar to the rescue! anywho, that was back on, did the center punch to ensure it wouldn't loosen (like manaul says to) and the put back my clutchpack. then put back on the pressure plate and install heavy duty clutch springs. ***FYI, the guy i bought this stuff from told me that when you use these for a while, your clutch slave support will begin to crack, and to get a clutch slave support bracket*** now, since i am probably going to put the stock springs back in after i take it to the track, i dicided not to do this, nor did i have the part...so, then it was together again, and i took it for a ride...WOW, it kinda removed that KA-THUNK that a bike makes when you downshift the bike into first from neutral. the clutch lever is a lot stiffer, a little too stiff for long riding in my opinion (or at least in the city, highway is probably fine since no shifting). now there was one thing the guy also warned me about and i have felt a little. if you downshift a little abruptly, it will fishtail in the tinniest of ways. but if you watch it and know that it has this tendency, or even if you don't, it probably won't cause much in the way of problems...unless you downshit hard in a corner, but who would do that anyway? so here are my pics:

btw, the one of the two springs is stock vs. heavy duty (you can guess which is which

)